2019-11-25

A nickel ore market

Indonesia is located at the intersection of the Pacific Ocean and the Indian Ocean, across the equator, with a land area of 1.919 million square kilometers and an ocean area of 3.16 million square kilometers (excluding the Special Economic Zone). Composed of tens of thousands of islands, Indonesia is the largest archipelagic country in the world.

Indonesia, which is rich in resources, has strong economic complementarity with China. Indonesia can provide China with mineral resources such as oil, natural gas, copper, aluminum, nickel and tin. China's investment can also drive the local economic development of Indonesia.Due to rich mineral resources and low energy prices, many Chinese non-ferrous metal enterprises have attracted investment in Indonesia, of which the investment in the nickel market is the most eye-catching and has a far-reaching impact on the global nickel market.The news that Indonesia banned the export of low-grade ores triggered a continuous sharp rise in nickel prices. This paper introduces the development of Indonesia's nickel market from the perspective of nickel ore, ferronickel, wet process project, stainless steel project, etc.

Nickel is a kind of metal with abundant reserves on earth.Nickel ores are divided into two types, one is laterite nickel ore, and the other is sulfide ore. the corresponding components are nickel oxide and nickel sulfide. The global reserves account for 60% and 40% respectively.Lateritic nickel ores are mostly open-pit mines, which are convenient to mine. However, due to the low grade and complex treatment process, the main nickel deposits mined in the world are sulfide ores. In terms of proportion, the annual output of nickel products produced by sulfide ores and lateritic nickel ores is roughly 55:45.Most of the copper nickel sulfide deposits found in the world have been developed and utilized, while the development of lateritic nickel ore has just started, which is the focus of future development.Nickel ore in Indonesia is laterite nickel ore.Laterite nickel ore is an oxide ore, which is mainly distributed in the equatorial region. Because it contains more iron and its color shows the red of iron oxide, it is called laterite nickel ore.

Indonesian nickel resources are concentrated in Sulawesi island and nearby islands.Sulawesi nickel resources account for about 80% of Indonesia's total nickel resources.Sulawesi island is a large island in Central Indonesia, with a total land area of 174600 square kilometers.Sulawesi island is shaped like a capital English letter "K", which is commonly known as big K island by local people.There are many high mountains and deep valleys and few plains on the island. The mountainous area accounts for a large proportion. Indonesia's green mountain base is located on the island.

reserves

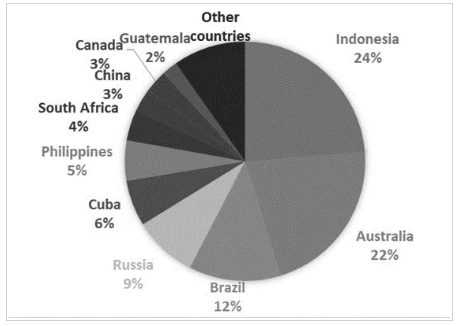

According to the data of the United States Geological Survey (USGS), in 2018, more than 130 million tons of nickel resources with a nickel content of more than 1% were identified in the world, of which 60% were lateritic nickel ores.The number of new sulfide deposits found in traditional mining areas has decreased, but a large number of nickel resources have been found in manganese crusts and nodules on the ocean floor.The global nickel reserves are relatively concentrated, and the reserves of the top 10 countries account for 95%.Due to the growth of stainless steel demand for nickel in recent years, Indonesia's nickel mine investment has increased. According to USGS data, Indonesia's nickel reserves increased significantly from 4.5 million tons to 21 million tons in 2018, becoming the country with the richest nickel resources, accounting for about 24% of the global reserves, followed by Australia, Brazil, Russia, New Caledonia, Cuba, the Philippines and other countries.

yield

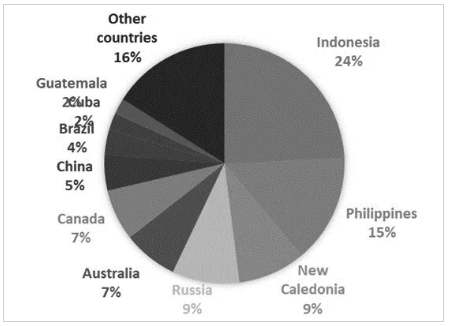

In 2018, the global nickel mine output was 2.18 million tons, an increase of about 2% year-on-year. Among them, the nickel mine output of the top six producing countries accounted for 72% of the total global output, including Indonesia, the Philippines, Russia, Canada, New Caledonia and Australia.According to USGS data, Indonesia's nickel mine output in 2018 reached 560000 tons, ranking first in the world, with an increase of 60%, accounting for about 24% of the global output.

Export

According to the data released by the Ministry of energy of Indonesia, the export volume of nickel ore in Indonesia in 2018 was 22million tons, with a sharp year-on-year increase of 450%.The huge change stems from the change of mining policy in Indonesia.We temporarily divide Indonesia's mining policy in recent years into four stages:The first stage is before 2014, the second stage is the comprehensive prohibition stage from 2014 to 2017, the third stage is the stage of allowing the export of low-grade ores from 2017 to 2019, and the fourth stage is the stage of prohibiting the export of low-grade ores after 2020 (the export of nickel ores will be completely stopped again).

Phase I

Before the ban on the export of laterite nickel ore in 2014, Indonesia exported a large amount of laterite nickel ore.By 2013, the export volume reached a peak of more than 60 million tons.In 2014, Indonesia's ban on mining and export policy gave birth to the large-scale development of ferronickel projects. Before 2014, the export volume of ferronickel in Indonesia was less than 100000 tons, while in 2017, the value exceeded 1million tons.

Second stage

In fact, long before Indonesia banned the export of nickel ore this time, Indonesia also banned the export of nickel ore in 2014.At that time, the Indonesian government hoped to encourage enterprises to conduct smelting and processing locally by changing the way of simply exporting resources, so as to improve the added value of products and promote employment and economic growth on the one hand.Therefore, the Indonesian government announced a total ban on the export of unprocessed raw ore from January 12, 2014, and raw ore must be smelted or refined locally before export.

In the middle of 2014, nickel prices rose to more than $2000 / ton.However, the mining ban in that year did not make nickel prices continue to rise. After Indonesia banned the export of raw ores in January 2014, lateritic nickel ores exported from the Philippines to China and early stockpiles made up the gap.The expected gap did not appear, but the import of nickel ore continued. In the middle of 2014, nickel prices fell again.

The third stage

From January 12, 2017, Indonesia resumed the export of nickel ore.According to the mining regulations in 2017, Indonesia plans to suspend the export of unprocessed ores on January 12, 2022. Previously, miners will be given five years to build smelters in China, but the mines allowed to export must meet two conditions:First, 30% of the smelting capacity must be used for processing low-grade ores, and the rest can be used for export;Second, the smelting project must be completed within five years and must pass the construction progress verification of the Indonesian government every six months, otherwise it will be disqualified.

The fourth stage

From January 1, 2020, the export of nickel ore with a content of less than 1.7% will no longer be allowed, that is, the export of nickel ore will be completely prohibited.

B ferronickel Market

At present, China and Indonesia mainly use laterite nickel ore to produce nickel pig iron. Indonesia's NPI has a rapid growth rate due to its cost advantage.If the import price of nickel ore in China is too high due to the ore ban, China's high-cost nickel pig iron production capacity may be replaced by Indonesia's production capacity. Therefore, it is expected that next year's nickel iron production will fall for China and rise for Indonesia.It is estimated that China's NPI output will fall below 500000 tons in 2020, and Indonesia's NPI output will rise to 550000 tons.

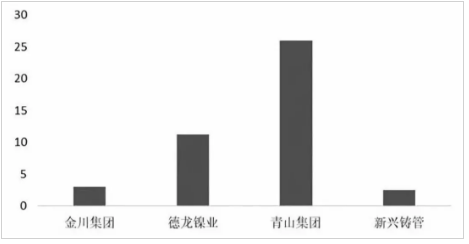

As Indonesia's nickel resources are mainly concentrated in Sulawesi island, most of Indonesia's NPI plants are set up in this region. Among them, in central Sulawesi province, there are Qingshan group and new Hualian, as well as Hengshun Zhongsheng and Yinhai Wanxiang, which are likely to be put into operation in the future. In March 2019, the output of nickel pig iron in this province accounted for about 64% of Indonesia's output of nickel pig iron in March.In addition, there are Delong and ifishdeco in Southeast Sulawesi province, whose output accounted for about 24% of Indonesia's nickel pig iron output in March.

The remaining major investment areas are North Maluku Province, South Sulawesi, Maluku province and Banten province.In North Maluku Province, there are emerging cast pipes and Jinchuan project that is expected to be put into operation this year, as well as wedabay Industrial Park participated by Aoyama group, which also accounts for about 9% of Indonesia's nickel pig iron production in March;South Sulawesi province has Huadi industry;There is Zhenshi project in Maluku province;Banten province has two enterprises with Indonesian backgrounds:Indoferro and century metallurgy.

C stainless steel market

When it comes to ferronickel market, we have to mention the stainless steel market in Indonesia.As an upstream supporting product of stainless steel, ferronickel is closely related to stainless steel.

In terms of nickel iron stainless steel industry, Qingshan group has the fastest development.Castle Peak Industrial Park is a foreign-funded mining project with the fastest capital, fastest construction speed and most fruitful results since Indonesia issued the mining ban order.The park is planned to cover an area of more than 1300 hectares, mainly equipped with a thermal power plant with a total capacity of more than 1000 MW, a 100000 ton wharf, an airstrip and a living area with a total construction area of about 200000 square meters, with a total investment of 5billion US dollars.

Since the establishment of the park in July 2013, Castle Peak Holdings has put into operation three projects in less than four years, and achieved production within four months of production, and achieved stable overproduction within one year. The output exceeded the original design output and operated stably.The submerged arc furnace of the Qingshan stainless steel ferronickel project in Indonesia has been powered on for trial production, completing the complete industrial chain of "nickel ore ferronickel stainless steel" in Indonesia.

According to the data, Indonesia's NPI output in 2019 was 380000 tons, which is expected to increase to 550000 tons in 2020, of which Castle Peak plans to produce 260000 tons, accounting for about 50%.At present, Castle Peak has a stainless steel production capacity of 3million tons in Indonesia, and most of this raw nickel is consumed by its own stainless steel plants.

D wet project market

Another market that has attracted much attention is the growing demand for new energy vehicle batteries.Stimulated by the rise of the electric vehicle industry, different institutions and companies believe that the predicted demand for battery nickel in 2025 is about 420000-550000 tons, and the increased demand for nickel in power batteries in the future needs new capacity supplement.along withNew energy vehiclesThe growth of battery demand and nickel sulfate demand will raise the operating range of nickel price in the future.According to the industry operation data, the breakeven point of nickel hydrometallurgy from laterite nickel ore is about 11500 US dollars / ton. The market expects that it is a high probability event that the nickel price will remain above 16000 US dollars / ton in the future, which has attracted many Chinese enterprises to enter the hydrometallurgy project of laterite ore in Indonesia to meet the demand for raw materials of nickel sulfate in the future.

The development of laterite nickel ore in Indonesia has resource advantages, cost advantages and mature project experience, so it has attracted a lot of investment.The characteristics of Indonesian mining industry are mainly reflected in its resources, costs, construction implementation, environmental protection and infrastructure. Indonesia's resources have advantages in both quantity and quality. In addition, it also has advantages in labor and energy costs. Chinese standards can be adopted for construction, which can reduce the level of investment;Low environmental protection requirements and low environmental protection costs.However, investment in Indonesia is not without risks. It should be noted that the overall infrastructure in Indonesia is relatively backward, which may increase the investment cost of supporting facilities, and may increase environmental protection requirements in the later stage.

At present, the main wet process projects in Indonesia include:

The Obi Island project of Liqin mining and Indonesia halida group has an investment of 5-6 billion yuan, with an annual output of 30000 tons of nickel cobalt wet intermediates and a physical quantity of 240000 tons. It is expected to be put into operation in 2020.

Qingshan, Zhenshi, Huayou / weidabei Industrial Park project /eramet, the project has two phases. The first phase of the project plans to invest a total of 5billion dollars, including 12 rkef production lines, 1 wet nickel smelter, supporting 3 coal-fired power plants and 3 large wharfs. Among them, four rkef lines cooperated by Qingshan and Eramet will be put into operation in the first half of 2020.

The Sulawesi island project of Qingshan industry, greenmead and Bangpu recycling (catl Holdings) plans to invest US $700million in the early stage of the project, but according to incomplete information, it is expected that some additional investment will be required in the later stage.At present, the project is in the process of preliminary site clearance, geological exploration, general layout design of the park and business negotiation in Indonesia. It is planned to be completed by the end of 2020 and is expected to be completed in 2021.After the completion of the plan, 50000 tons of nickel hydroxide intermediates, 150000 tons of battery grade nickel sulfate crystals, 20000 tons of battery grade cobalt sulfate crystals and 30000 tons of battery grade manganese sulfate crystals will be produced annually.

Huayou cobalt Co., Ltd., a wholly-owned subsidiary of Huayou cobalt industry, and QingChuang international, woyuan holdings, IMIP, longsincer Sulawesi island project, with a total investment of 1.28 billion US dollars. The production scale of the project is 60000 tons of nickel metal per year, and 30000 tons of nickel metal per year in the first stage of construction.

0755-89480969

info@powercome.hk

B1202, building 1, Mogen Fashion Industrial Park, No. 10, shilongzi Road, Xinshi community, Dalang street, Longhua District, Shenzhen

www.powercome.hk