Aluminum plastic composite film (hereinafter referred to as "aluminum plastic film") is mainly a composite material composed of on/al/cpp (outer nylon layer / middle aluminum foil layer / inner heat sealing layer), and the layers are bonded by adhesives.Aluminum plastic film is soft packagelithium batteryAs one of the key materials of packaging, it plays a role in protecting the internal core materials, and has strict requirements in terms of barrier property, cold stamping formability, puncture resistance, chemical stability and insulation.Compared with cylindrical and square aluminum shell, flexible battery has obvious advantages in energy density, safety and flexibility, and has been widely used in 3C consumer, new energy vehicles and energy storage fields.

1、Structural characteristics of aluminum plastic film

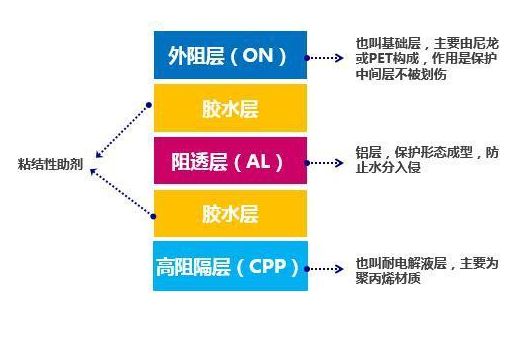

The functional structure of aluminum-plastic film is generally three layers, including external nylon layer (on layer), intermediate aluminum foil layer (Al layer), and internal heat sealing layer (CPP layer or PP layer). The main raw materials include nylon, aluminum foil, polypropylene CPP and binder.

The external on layer protects the Al layer from scratch, and the outer material is required to be puncture resistant and impact resistant;

Al layer acts as a barrier to prevent moisture intrusion and block oxygen to protect the contents of the battery;

The inner layer is an electrolyte resistant layer to prevent the leaked electrolyte from corroding the Al layer, which requires high composite strength with the aluminum foil layer.

The key to the production of aluminum-plastic film is to press and bond the three layers of functional materials evenly and firmly through adhesive additives between layers.

Therefore, the thickness of conventional aluminum-plastic film on the market is generally divided into 88 μ m、113 μ m、153 μ M third gear, 86 of which μ M and 113 μ M two levels for consumer electronics, 153 μ M is used in the field of lithium batteries for new energy vehicles and industrial energy storage.

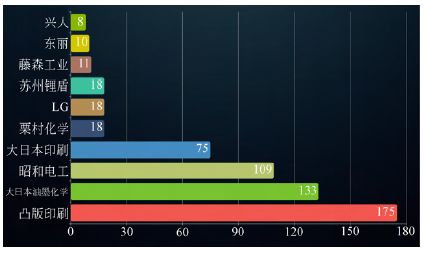

Price chart of some aluminum plastic films

2、Market demand analysis of aluminum plastic film

The penetration of power field has accelerated, and the soft packed lithium battery has developed at a high speed.

The first tier of soft pack lithium battery technology is mainly Japanese and Korean enterprises, especially LG, which is the global leader in soft pack lithium battery. Its products have better energy density and stability. Chevrolet, Nissan and other car companies mainly use LG soft pack battery. On the whole, Japan and South Korea and other international car companies have a high degree of recognition for the technical route of soft pack lithium battery.

Domestic mainstream electric vehicle enterprises are also accelerating the application of soft pack batteries.

BAIC, SAIC and other passenger car enterprises have begun to try to use soft pack batteries, among which Wanxiang A123 and Funeng technology soft pack batteries occupy the mainstream.

The domestic ternary soft package technology has made significant progress, and the energy density has increased significantly. Taking Funeng technology as an example, the monomer energy density reaches 220wh/kg, and after the pack, it is between 140-160wh/kg.

With the rise of the soft pack trend, power battery enterprises have increased the expansion of soft pack production in order to seize the opportunity. By the end of 2017, the production capacity of nine soft pack battery enterprises will reach 27gwh.

We believe that the demand for lithium batteries will grow side by side with the penetration rate of soft packs. In 2020, the penetration rate of soft packs will be about 41%. The demand for soft packs will reach 59gwh and the gagr will be 35%.

The aluminum-plastic film market is growing rapidly, and import substitution is accelerating.

The global (China) aluminum plastic film market and technology have been monopolized by a few enterprises in Japan and South Korea. The domestic production rate is only 5%, and there is a lot of room for import substitution.

Through the acquisition of Japanese relief printing (t&t) aluminum plastic film business, Xinlun technology has a current production capacity of 2million Ping / month, and the total production capacity in the future will reach 6million Ping. We believe that with the large-scale production of domestic aluminum plastic film, it is expected that the market share of domestic aluminum plastic film will exceed 10% in 2017 and reach 40% by 2020.

According to the statistics of network data, according to the demand for power energy storage and 3C soft packed lithium battery from 2017 to 2020, according to the price of different types of power energy storage and 3C aluminum-plastic film, it is calculated that the demand for aluminum-plastic film in China from 2017 to 2020 is 95 million square meters, 127 million square meters, 172 million square meters and 236 million square meters, with the corresponding market space of 3.1 billion yuan, 3.9 billion yuan, 4.9 billion yuan and 6.3 billion yuan, and the gagr is 26%.

Forecast data of aluminum plastic film market

3、Technical characteristics of aluminum plastic film

At present, the performance of aluminum-plastic film products in China can only reach the level of Japanese enterprises in a few technical indicators. The main problem is that the electrolyte resistance and punching depth are not qualified. The punching depth of domestic aluminum-plastic film is about 5mm, that of foreign products is 8mm, or even 15mm, and there is still a certain gap with foreign products on the whole.

Especially the reaction conditions and precision control. In the manufacturing process of such high-precision materials, the difference is often a thousand miles, and the difficulty of process control is reflected in the minute.

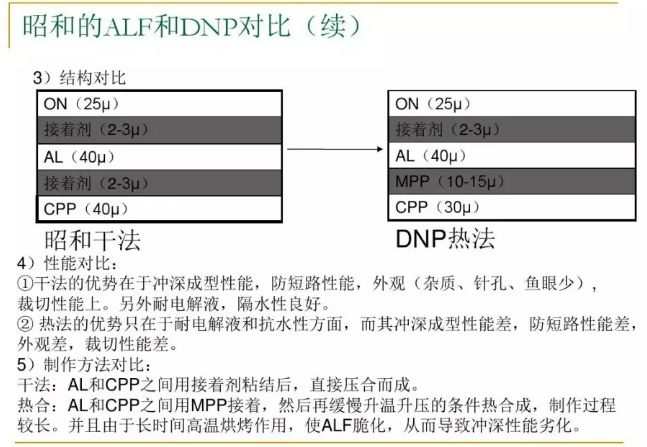

The preparation of aluminum plastic film mainly includes dry method and thermal method.

The dry process is formed by bonding aluminum and polypropylene with adhesive and then pressing them directly. The thermal process is formed by bonding aluminum and polypropylene with MPP and pressing them under slow temperature rise and pressure rise.

The main advantages of dry process aluminum-plastic film are good punching forming effect, good appearance consistency, not easy to have pinholes, fish eyes, impurities and other defects, but its electrolyte resistance is poor.

The thermal process can improve the adhesion between Al layer and PP layer, and greatly improve the anti electrolyte swelling and falling off ability of the inner surface layer. However, this specially treated MPP needs a higher temperature to melt it to play a bonding role. After cooling, it is easy to curl inward due to the large difference between the shrinkage coefficient of MPP and PP.

Aluminum plastic film is an important part of soft pack battery. Its upstream is mainly composed of four structural raw materials nylon film, aluminum foil, CPP and adhesive. Its midstream is the manufacturing of aluminum plastic film products and the preparation of soft pack batteries, and its downstream is the application field of soft pack batteries.

aluminium

Process comparison of main plastic film manufacturers

4、Patent technology analysis of aluminum plastic film

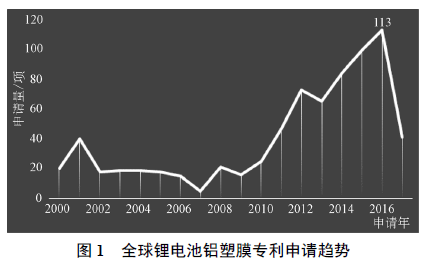

From 2000 to 2010, the number of patent applications for aluminum-plastic film of soft packed lithium batteries in the world generally maintained a steady growth, with an average annual application of about 20. At this stage, the aluminum-plastic film industry is in the early stage of development, with a small number of enterprises entering the aluminum-plastic film industry and a small number of corresponding patent layout.

Since 2011, with the rapid development of the global lithium battery industry, especially the vigorous development of soft pack power lithium batteries, aluminum-plastic film, as a key component of soft pack lithium batteries, has received great attention. Many enterprises have entered the aluminum-plastic film industry, and domestic enterprises have also started the R & D and production of aluminum-plastic film. The increase in patent layout has driven the rapid growth of global patent applications, By 2016, the number of patent applications had reached a peak of 113.

It should be noted that the decline in the number of applications in 2017 is mainly due to the fact that some patents have not yet been published, resulting in a small number of patent applications. It is foreseeable that the number of patent applications for aluminum-plastic film will continue to grow at a high speed in the future.

The main technology exporting countries in the field of aluminum-plastic film for soft packed lithium batteries are Japan, China and South Korea. Japan has an absolute technological advantage in the field of aluminum-plastic film for soft packed lithium batteries, with 562 patent applications, accounting for 73.6% of the global application volume.

Japan printing, Showa electric, relief printing Co., Ltd. and other world-renowned aluminum-plastic film manufacturers not only occupy a monopoly position in the global aluminum-plastic film market, but also take the lead in the patent layout in the field of aluminum-plastic film, making Japan far ahead of other countries and regions in the export of patented technology in the field of aluminum-plastic film.

In recent years, China's consumer electronics market has been booming, and the new energy vehicle market is also in the ascendant. The rapidly expanding downstream demand has driven the demand for lithium batteries, especially soft packed lithium batteries, to continue to strengthen, which has generated a strong demand for aluminum-plastic film, which has also provided a huge development opportunity for domestic aluminum-plastic film enterprises. The technological research and development of domestic aluminum-plastic film has also shown a positive trend, driving the increase in the number of domestic patent applications.

LG and Kimura Chemical Co., Ltd. of South Korea also have high technical advantages in the field of aluminum-plastic film, making the output of Korean patent technology ranked third, while the United States and Europe have few patent applications in the field of aluminum-plastic film.

As an emerging force in the global aluminum-plastic film industry for soft packed lithium batteries, Chinese applicants have also begun to focus on patent layout in the field of aluminum-plastic film in recent years.

However, there is still a big gap compared with international leading enterprises. Suzhou Lidun energy storage materials Co., Ltd. has more than 10 invention patent applications, while other domestic well-known enterprises, such as Shanghai Zijiang New Material Technology Co., Ltd., Daoming Optical Co., Ltd., Foshan fosu Technology Group Co., Ltd Dongguan Zhuoyue New Material Technology Co., Ltd. and Mingguan New Material Co., Ltd. have significantly less patent technology reserves, less than 8.

5、Characteristics of domestic aluminum plastic film market

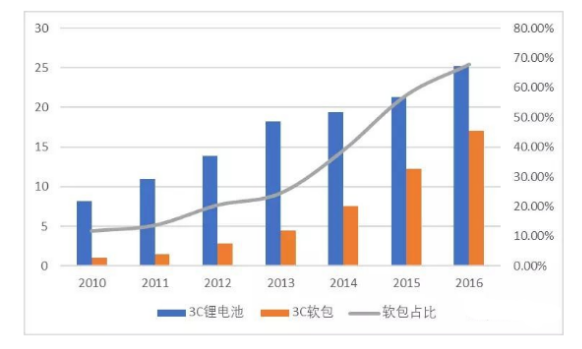

Due to its flexible shape design, high volume and mass energy density, and in line with the trend of miniaturization and thinness of electronic products such as mobile phones and tablet computers, the penetration rate in 3C battery field has been continuously improved, and the penetration rate in 3C battery field has been continuously increased, from 5% in 2010 to nearly 70% in 2016.

However, as the growth rate of traditional consumer electronics such as mobile phones, tablets and laptops has slowed down, it has entered a mature period, and the growth rate is expected to maintain about 10%.

Production of 3C lithium batteries and soft packed lithium batteries in China from 2010 to 2016

At present, the mainstream electric vehicle enterprises in China are accelerating the application of soft pack batteries. BAIC, SAIC and other passenger vehicle enterprises have begun to try to use soft pack batteries, among which Wanxiang A123 and Funeng technology soft pack batteries occupy the mainstream.

At the same time, the domestic ternary soft package technology has made significant progress, and the energy density has increased significantly. Taking Funeng technology as an example, the monomer energy density has reached 220wh/kg, and after the pack, it is between 140-160wh/kg.

With the rise of the soft pack trend, power battery enterprises have increased the expansion of soft pack production in order to seize the opportunity. By the end of 2017, the production capacity of nine soft pack battery enterprises will reach 27gwh.

We believe that the demand for lithium batteries will grow side by side with the penetration rate of soft packs. In 2020, the penetration rate of soft packs will be about 41%. The demand for soft packs will reach 59gwh and the gagr will be 35%.

Facing the huge market temptation, domestic enterprises have also deployed lithium battery soft package aluminum plastic film business.

Shin Lun technology, through cross-border mergers and acquisitions in 2016, the assets and all patents of the Japanese triple factory engaged in the production of aluminum-plastic film under Japanese t&t;

Daoming optical aluminum plastic film was put into production in the fourth quarter of 2016;

Dongguan Zhuoyue, a wholly-owned subsidiary of putailai, successfully solved the problem of the adhesion between the CPP layer of aluminum plastic packaging film and aluminum foil layer by using the self-developed thermal composite process and secondary composite process;

Fujian film has a total investment of 1.2 billion yuan. The aluminum-plastic film project has been started in Liancheng Industrial Park, making up for the short board that domestic lithium battery flexible aluminum-plastic composite film is heavily dependent on imports, and becoming the largest R & D and production base of lithium battery flexible aluminum-plastic film in China.

The aluminum-plastic film was put into production in the fourth quarter of 2016 and entered a stable mass production stage in the second quarter of 2017. The performance indicators of the company's aluminum-plastic film are relatively consistent with those of similar products of foreign brands, and all performance indicators meet or exceed the recognized technical performance requirements in the industry. It is one of the few enterprises in China that can mass produce aluminum-plastic film, and the product quality has been gradually recognized in the market.

After early market development, dominion optics has received orders from more than 30 3C lithium battery enterprises in 2017. In 2017, the sales volume of aluminum-plastic film reached 1031400 square meters, realizing a sales revenue of 20.4997 million yuan, and the average sales unit price was 19.88 yuan / square meter (excluding tax).

After opening the market in 3C field, dominion optics began to focus on the field of power batteries.

Daoming optical's power aluminum-plastic film continued to send samples to power battery manufacturers in 2017, but because power enterprises are more cautious in introducing domestic aluminum-plastic film, the test evaluation period and test times are longer than those of consumer products.

At present, the development of major aluminum-plastic film enterprises is as follows:

On August 1st, 2016, it completed the acquisition of the "lithium battery aluminum plastic film project" under t&t of Japan, including the lithium battery aluminum plastic film factory with a monthly capacity of 2million square meters, relevant patents and proprietary technologies, and the exclusive right to operate in the Chinese market. At the end of 2016, it launched the construction of Changzhou functional materials industrial base, and planned to build two sets of lithium battery aluminum plastic film production lines with a capacity of 300 square meters / month.

From May, 2018 to December, 2020, Funeng technology purchased aluminum-plastic film products for lithium-ion batteries from Xinlun composites. The demand for aluminum-plastic film is planned to be 19 million square meters in total, and the total sales revenue is expected to be no less than 500 million yuan.

In 2011, Zijiang enterprises began to test sell aluminum-plastic film. In order to rapidly industrialize the aluminum-plastic film project, Zijiang enterprises stripped the aluminum-plastic film project from Zijiang color printing in 2012 to prepare for the establishment of Shanghai Zijiang New Material Technology Co., Ltd.

After years of research and development, aluminum plastic film, the packaging material of soft packed lithium battery developed by Shanghai Zijiang, has passed the certification of ATL, Guangyu, Lishen and other large lithium battery manufacturers, and has independent intellectual property rights.

In 2016, Zijiang enterprises increased the research and development of new products such as lithium batteries, aluminum-plastic films, and strive to achieve large-scale mass production quickly.

Sudahuicheng, founded in 2008 and headquartered in Jiangyin, Jiangsu Province, was launched on the new third board in December 2014. It is a high-tech enterprise committed to building a leading aluminum-plastic film for lithium batteries in China.

The company introduced a complete set of aluminum-plastic film production equipment for lithium batteries from Japan. Since its inception, it has vigorously introduced production and equipment backbones with professional knowledge of the industry, and simultaneously cultivated a number of professional equipment operation and production talents.

The company adopts the coextrusion composite process, and uses the coextrusion high-temperature adhesive resin layer to bond the aluminum foil and PP heat sealing layer. The products have excellent electrolyte corrosion resistance and good packaging state;

The thickness of PP layer of the product is adjustable, which can be adjusted within a certain range according to the needs of customers, and can fully meet the requirements of different products of customers.

At present, the company's aluminum-plastic film products are in the stage of mass production.

Buddha plastic technology

The aluminum plastic film project was initiated in 2008, and the product structure design and key performance breakthroughs were completed from 2008 to the beginning of 2011;

From 2011 to the middle of 2012, complete the construction of plant and equipment, and enter the industrialization stage;

Trial production began in mid-2012, and key projects were delivered

Customers conduct batch trial evaluation, and the market sales will be officially carried out at the beginning of the year.

In less than a year, the aluminum-plastic film of fosu technology has been delivered to more than 100 customers, and most of the trial battery factories are entering the stage of packaging and use of batch batteries.

In April 2016, fosu technology said on the investor interaction platform that aluminum-plastic film is a new material independently developed by the company, which is mainly used in polymer lithium-ion batteries for small appliances such as mobile communications and notebook computers, as well as flexible packaging shell packaging materials for ordinary lithium-ion batteries.

Dongguan Zhuoyue was founded in 2011 and originally belonged to the aluminum plastic film division of Dongguan zhuogo. It began small experiments in 2012 and was registered independently in 2015.

The types of aluminum plastic film products are:

one hundred and thirteen μ M (silver), 88 μ M (silver), 115 μ M (black), 91 μ M (black), mainly used in digital battery enterprises.

In November 2015, Dongguan Zhuoyue released the environmental impact report of construction projects, saying that the company invested 20million yuan to build a 1million square meter aluminum plastic film project.

Article source:Battery China Network